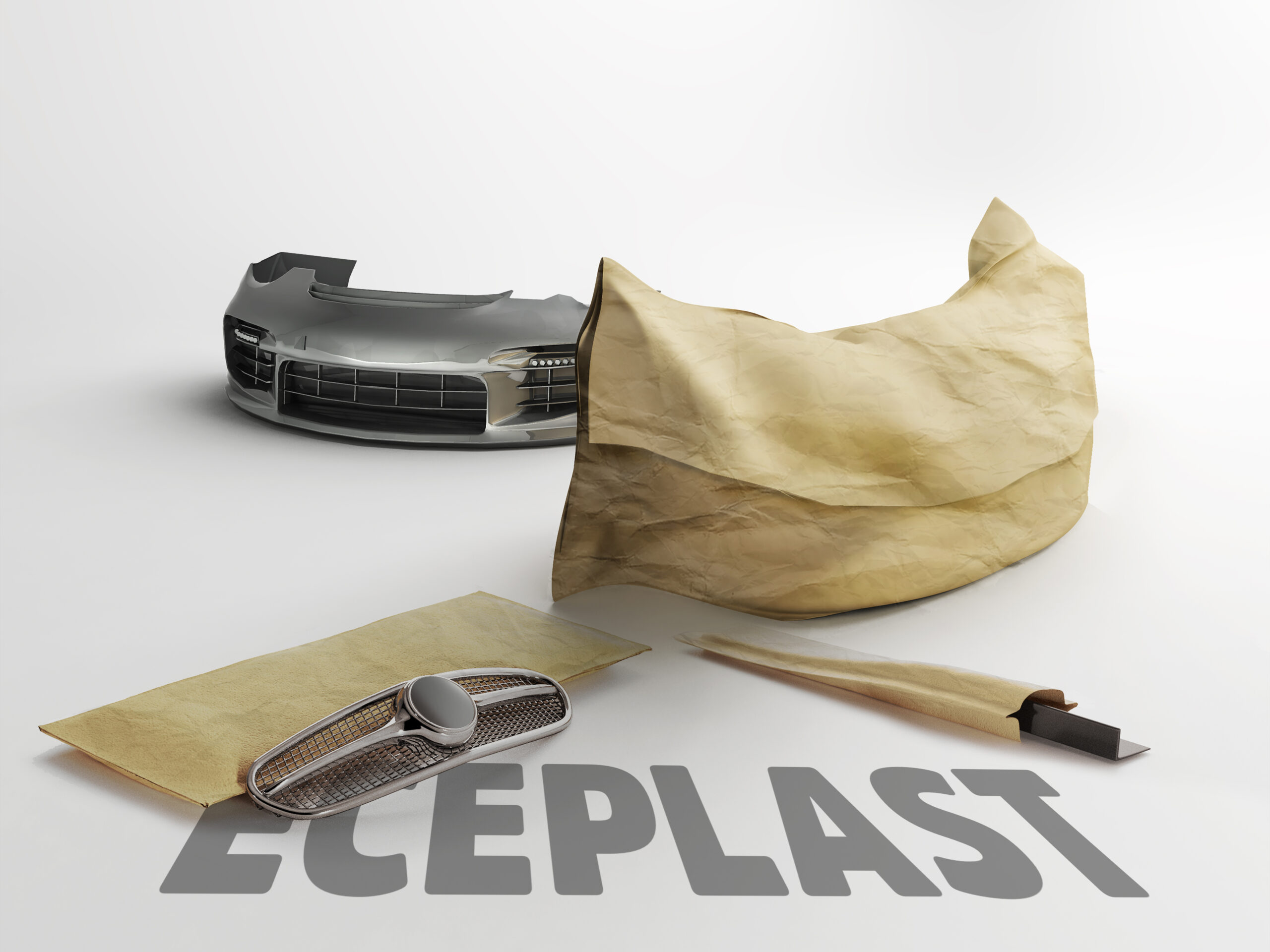

PROTECTIVE PAPER SACKS

Ensure a reliable protection for bulky, sensitive and irregularly shaped items, typically automotive spare-parts, granting the lowest CO2 footprint against cardboard boxes and plastic bubble foils.

Suitable for:

AUTOMOTIVE SPARE PARTS

Bumpers

Grills

Spoilers

DESIGNED TO

- Lower costs of packaging and handling.

- Reduce space and secondary packaging.

- Prevent condensation.

ECO-DESIGN

Protective Paper Sacks are the most sustainable packaging for bulky spare parts. From row material selection, as 70% of the paper used is recycled, until its total recycle after use.

Independent Life Cycle Assessment (LCA) certifies that the Protective Paper Sacks have only 1/3 of CO2 footprint compared to the alternative plastic bubble foil for automotive spare parts.

MADE OF

Multiple layer of different type of paper: Kraft, fluting recycled embossed, machine-glatt, tissue.

OPTIONS

- From 2 to 5 Layers composition

- Width range from mm 300 up to mm 1200

- External layer printable with customers logo and product information

- Long side open (for bumpers)

- Tubular (for spoilers)

- Handles sacks (for side windows)

- Tissue sacks (for chrome parts)

- Adhesive tape closure